Mark Dominus (陶敏修)

mjd@pobox.com

Archive:

| 2025: | JFMAMJ |

| JAS | |

| 2024: | JFMAMJ |

| JASOND | |

| 2023: | JFMAMJ |

| JASOND | |

| 2022: | JFMAMJ |

| JASOND | |

| 2021: | JFMAMJ |

| JASOND | |

| 2020: | JFMAMJ |

| JASOND | |

| 2019: | JFMAMJ |

| JASOND | |

| 2018: | JFMAMJ |

| JASOND | |

| 2017: | JFMAMJ |

| JASOND | |

| 2016: | JFMAMJ |

| JASOND | |

| 2015: | JFMAMJ |

| JASOND | |

| 2014: | JFMAMJ |

| JASOND | |

| 2013: | JFMAMJ |

| JASOND | |

| 2012: | JFMAMJ |

| JASOND | |

| 2011: | JFMAMJ |

| JASOND | |

| 2010: | JFMAMJ |

| JASOND | |

| 2009: | JFMAMJ |

| JASOND | |

| 2008: | JFMAMJ |

| JASOND | |

| 2007: | JFMAMJ |

| JASOND | |

| 2006: | JFMAMJ |

| JASOND | |

| 2005: | OND |

Subtopics:

| Mathematics | 245 |

| Programming | 99 |

| Language | 95 |

| Miscellaneous | 75 |

| Book | 50 |

| Tech | 49 |

| Etymology | 35 |

| Haskell | 33 |

| Oops | 30 |

| Unix | 27 |

| Cosmic Call | 25 |

| Math SE | 25 |

| Law | 22 |

| Physics | 21 |

| Perl | 17 |

| Biology | 16 |

| Brain | 15 |

| Calendar | 15 |

| Food | 15 |

Comments disabled

Thu, 16 Nov 2006

Etch-a-Sketch blue-skying, corrected

In my last article I

discussed a scheme for improving the Etch-a-Sketch which contained a serious

mechanical error. I was discussing attaching gears to the two knobs

of the Etch-a-Sketch to force them to turn at the exact same rate. Supposing

that the distance between the knobs is 1 unit, I said, then we can

gear the two knobs together by attaching a gear of radius 1/2 to each

knob; the two gears will mesh, and the knobs will then turn at the same

rate, in opposite directions. This was fine.

Then I went astray, and suggested adding an axle peg midway between the two knobs, and putting gears of radius 1/3 on the peg and on the two knobs. This won't work.

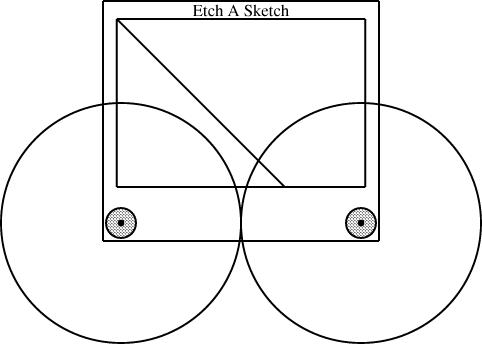

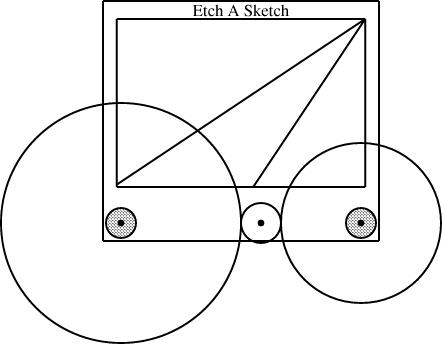

The one person who wrote to me to ask about the problem is a very bright person, but been seriously confused about how I was planning to set up the gears, so I evidently I didn't explain it very well. It needed a picture. So this time I'm going to try to get it right, with pictures. Here is an Etch-a-Sketch:

Here are some gears, which happen to have radii 1/3, 1/4, and 1/6:

Here's a picture of an Etch-a-Sketch with a radius-1/2 gear mounted on each knob:

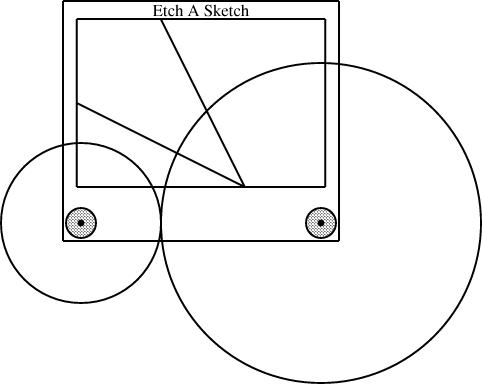

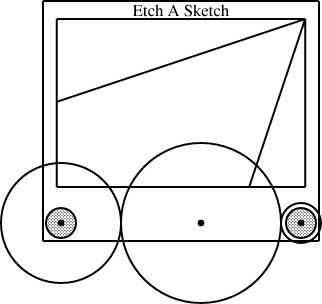

Here the knobs have been fitted with different-sized gears, one with radius 1/3 and the other with radius 2/3:

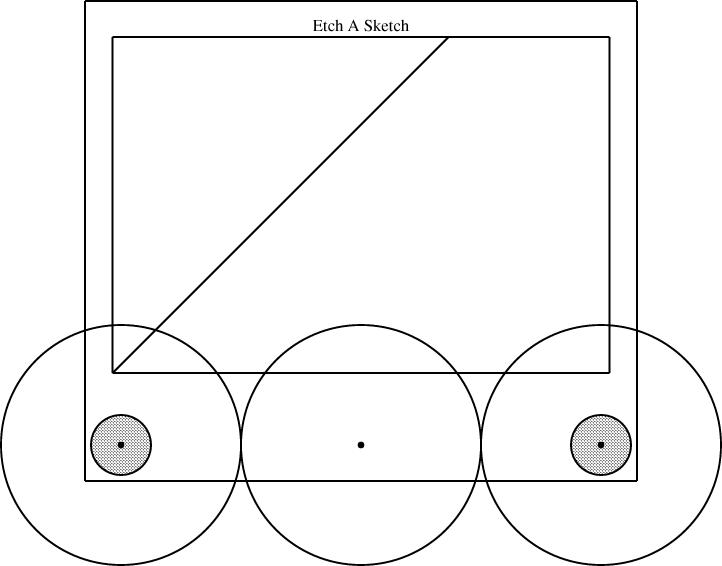

Then I suggested that you could drill a little hole in between the two knobs, and use it to mount a third axle and a third gear. If all three gears are the same size, the two knobs are forced to turn at the same rate, this time in the same direction, and you get a line with slope 1, from southeast to northwest:

This wrecks the rest of the details of my other article. Since we were already including gears of size 1/2 and 1/3, I reasoned, we can throw in a gear of size 1/6 and get some new behaviors from the 1/2 + 1/3 + 1/6 combination. The corresponding combination for 1/2 and 1/4 is 1/8:

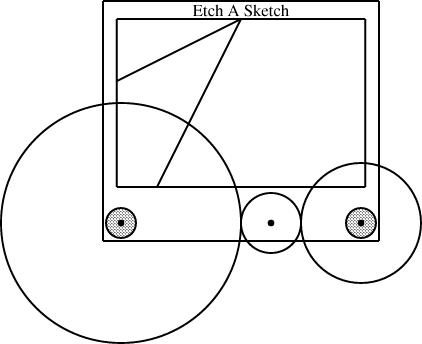

So what next? The calculations are a bit less obvious than they were back in the happy days when I thought that installing two gears of size p and q left space for one of size 1-(p+q). It's tempting to consider a radius-1/3 gear next, since it's the simplest size I haven't yet installed. But to mount it on the knobs along with a size-1/2 gear, we need to include a size-1/12 gear to go in between:

Once we have the size-1/12 gear, we can mount it with the size-1/4 and size-1/3 that we already had:

[Other articles in category /games] permanent link